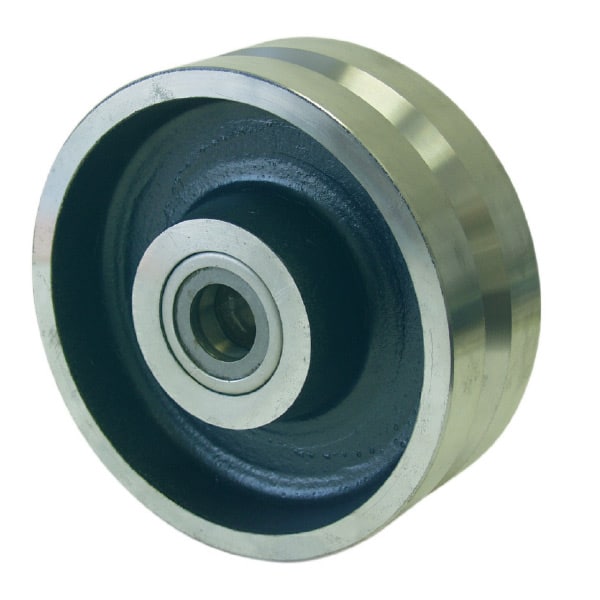

Industrial V-Groove Wheels

At RWM Casters, our customizable V-groove industrial track wheels are available with high-strength cast-iron (VI) castings or forged steel (VF) forgings. Each wheel is machined with a 90-degree groove that facilitates superior performance on an inverted angle iron track. As with all V-groove track wheels, it is imperative to ensure the inverted angle iron track is parallel for assuring smooth and constant tracking. Our engineers and designers understand this critical requirement and the importance of precision manufacturing to ensure proper operation of our V-groove wheels. To that end, you can rest assured that whether you choose a flat-faced cast-iron or forged steel wheel, RWM’s solutions will deliver the safe, dependable motion you require.

Features

| Wheel Bearings | Choice of straight roller bearing or tapered bearing |

| Temperature Range | -50° to +800°F |

| Hub Length | Can be cut or lengthened with spacers |

| Lubrication Fittings | Standard on 2-1/2″ and wider wheels |

| Bores | Various sizes available on some wheels |

| Keyways | Can be installed on most sizes |

Applications

V-Groove Wheels are used to control the flow of a load, for example, into an oven, between machines, over long distances, or where a “production line” sequence is required. |

| WS | Wheel Seals |

| ZF | Zerk Fittings on 2″ wide and smaller wheels |

| WHEEL DIAMETER | WHEEL WIDTH | CAPACITY | WHEEL TYPE | AXLE DIAMETER | STRAIGHT ROLLER BEARING | TAPERED BEARING | GROOVE WIDTH | GROOVE DEPTH | HUB LENGTH | APPROX WEIGHT |

|---|---|---|---|---|---|---|---|---|---|---|

| 4'' | 1-1/2" | 700 | 1/2″ | VIR-0415-08 | 7/8" | 7/16" | 1-7/8″ | 3.4 | ||

| 4'' | 1-1/2" | 700 | 5/8″ | VIR-0415-10 | 7/8" | 7/16" | 1-7/8″ | 3.4 | ||

| 4'' | 1-1/2" | 700 | 3/4″ | VIR-0415-12 | 7/8" | 7/16" | 1-7/8″ | 3.4 | ||

| 4'' | 2" | 800 | 1/2″ | VIR-0420-08 | 7/8" | 7/16" | 2-7/16″ | 4.5 | ||

| 4'' | 2" | 800 | 5/8″ | VIR-0420-10 | 7/8" | 7/16" | 2-7/16″ | 4.5 | ||

| 4'' | 2" | 800 | 3/4″ | VIR-0420-12 | 7/8" | 7/16" | 2-7/16″ | 4.5 | ||

| 5'' | 2" | 800 | 1/2″ | VIR-0520-08 | 7/8" | 7/16" | 2-7/16″ | 6.3 | ||

| 5'' | 2" | 800 | 5/8″ | VIR-0520-10 | 7/8" | 7/16" | 2-7/16″ | 6.3 | ||

| 5'' | 2" | 800 | 3/4″ | VIR-0520-12 | 7/8" | 7/16" | 2-7/16″ | 6.3 | ||

| 6" | 2" | 1000 | 1/2″ | VIR-0620-08 | VIT-0620-08 | 7/8" | 7/16" | 2-7/16″ | 7.2 | |

| 6" | 2" | 1000 | 5/8″ | VIR-0620-10 | 7/8" | 7/16" | 2-7/16″ | 7.2 | ||

| 6" | 2" | 1000 | 3/4″ | VIR-0620-12 | VIT-0620-12 | 7/8" | 7/16" | 2-7/16″ | 7.2 | |

| 6" | 2-1/2'' | 1500 | 3/4″ | VIR-0625-12-YY | VIT-0625-12-YY | 7/8" | 7/16" | 3″ | 11.2 | |

| 6" | 2-1/2'' | 1500 | 1″ | VIR-0625-16-SI-YY | 7/8" | 7/16" | 3″ | 11.2 | ||

| 6" | 2-1/2'' | 1500 | 1″ | VIR-0625-16-YY | VIT-0625-16-YY | 7/8" | 7/16" | 3″ | 11.2 | |

| 6" | 2-1/2'' | 1500 | 1-1/4″ | VIR-0625-20-YY | 7/8" | 7/16" | 3″ | 11.2 | ||

| 6" | 2-1/2'' | 2500 | 3/4″ | VIR-0625-12 | VIT-0625-12 | 7/8" | 7/16" | 3-1/2″ | 11.2 | |

| 6" | 2-1/2'' | 2500 | 1″ | VIR-0625-16-SI | 7/8" | 7/16" | 3-1/2″ | 11.2 | ||

| 6" | 2-1/2'' | 2500 | 1″ | VIR-0625-16 | VIT-0625-16 | 7/8" | 7/16" | 3-1/2″ | 11.2 | |

| 6" | 2-1/2'' | 2500 | 1-1/4″ | VIR-0625-20 | 7/8" | 7/16" | 3-1/2″ | 11.2 | ||

| 6" | 3'' | 3500 | 3/4″ | VIR-0630-12 | VIT-0630-12 | 7/8" | 7/16" | 3-1/2″ | 20 | |

| 6" | 3'' | 3500 | 1″ | VIR-0630-16 | VIT-0630-16 | 7/8" | 7/16" | 3-1/2″ | 20 | |

| 6" | 3'' | 3500 | 1″ | VIR-0630-16-SI | 7/8" | 7/16" | 3-1/2″ | 20 | ||

| 6" | 3'' | 3500 | 1-1/4″ | VIR-0630-20 | 7/8" | 7/16" | 3-1/2″ | 20 | ||

| 6" | 3'' | 7000 | 3/4″ | VFR-0630-12 | VFT-0630-12 | 1-3/8" | 11/16" | 3-1/2″ | 30 | |

| 6" | 3'' | 7000 | 1″ | VFT-0630-16 | 1-3/8" | 11/16" | 3-1/2″ | 30 | ||

| 6" | 3'' | 7000 | 1″ | VFR-0630-16-SI | 1-3/8" | 11/16" | 3-1/2″ | 30 | ||

| 6" | 3'' | 7000 | 1-1/4″ | VFR-0630-20 | VFT-0630-20 | 1-3/8" | 11/16" | 3-1/2″ | 30 | |

| 6" | 3'' | 7000 | 1-1/2″ | VFR-0630-24 | VFT-0630-24 | 1-3/8" | 11/16" | 3-1/2″ | 30 | |

| 6" | 3'' | 10000 | 1-1/4″ | VFT-0630-20-HD | 1-3/8" | 11/16" | 3-1/2″ | 30 | ||

| 8" | 2" | 1050 | 1/2″ | VIR-0820-08 | VIT-0820-08 | 7/8" | 7/16" | 2-7/16″ | 13.2 | |

| 8" | 2" | 1050 | 5/8″ | VIR-0820-10 | 7/8" | 7/16" | 2-7/16″ | 13.2 | ||

| 8" | 2" | 1050 | 3/4″ | VIR-0820-12 | VIT-0820-12 | 7/8" | 7/16" | 2-7/16″ | 13.2 | |

| 8" | 2-1/2'' | 3000 | 3/4″ | VIR-0825-12 | VIT-0825-12 | 7/8" | 7/16" | 3-1/2″ | 15.8 | |

| 8" | 2-1/2'' | 3000 | 1″ | VIR-0825-16-SI | 7/8" | 7/16" | 3-1/2″ | 15.8 | ||

| 8" | 2-1/2'' | 3000 | 1″ | VIR-0825-16 | VIT-0825-16 | 7/8" | 7/16" | 3-1/2″ | 15.8 | |

| 8" | 2-1/2'' | 3000 | 1-1/4″ | VIR-0825-20 | 7/8" | 7/16" | 3-1/2″ | 15.8 | ||

| 8" | 3'' | 5000 | 3/4″ | VIR-0830-12 | VIT-0830-12 | 7/8" | 7/16" | 3-1/2″ | 23.5 | |

| 8" | 3'' | 5000 | 1″ | VIR-0830-16-SI | 7/8" | 7/16" | 3-1/2″ | 23.5 | ||

| 8" | 3'' | 5000 | 1″ | VIR-0830-16 | VIT-0830-16 | 7/8" | 7/16" | 3-1/2″ | 23.5 | |

| 8" | 3'' | 5000 | 1-1/4″ | VIR-0830-20 | 7/8" | 7/16" | 3-1/2″ | 23.5 | ||

| 8" | 6000 | 3/4″ | VFR-0830-12 | VFT-0830-12 | 7/8" | 7/16" | 3-1/2″ | 30 | ||

| 8" | 6000 | 1″ | VFR-0830-16-SI | VFT-0830-16 | 7/8" | 7/16" | 3-1/2″ | 30 | ||

| 8" | 6000 | 1-1/4″ | VFR-0830-20 | VFT-0830-20 | 7/8" | 7/16" | 3-1/2″ | 30 | ||

| 8" | 6000 | 1-1/2″ | VFR-0830-20-SI | 7/8" | 7/16" | 3-1/2″ | 30 | |||

| 8" | 3'' | 6000 | 1-1/2″ | VFR-0830-24 | 7/8" | 7/16" | 3-1/2″ | 30 | ||

| 8" | 4" | 10000 | 1-1/4″ | VFR-0840-20-SI | 1-3/4" | 7/8" | 4-1/2″ | 30 | ||

| 8" | 4" | 10000 | 1-1/2″ | VFR-0840-24-SI | 1-3/4" | 7/8" | 4-1/2″ | 30 | ||

| 8" | 4" | 10000 | 2″ | VFR-0840-32 | 1-3/4" | 7/8" | 4-1/2″ | 30 | ||

| 8" | 4" | 15000 | 1-1/4″ | VFT-0840-20 | 1-3/4" | 7/8" | 4-1/2″ | 30 | ||

| 8" | 4" | 15000 | 1-1/2″ | VFT-0840-24 | 1-3/4" | 7/8" | 4-1/2″ | 30 | ||

| 10" | 3'' | 5000 | 3/4″ | VIR-1030-12 | VIT-1030-12 | 7/8" | 7/16" | 3-1/2″ | 21 | |

| 10" | 3'' | 5000 | 1″ | VIR-1030-16-SI | 7/8" | 7/16" | 3-1/2″ | 21 | ||

| 10" | 3'' | 5000 | 1″ | VIR-1030-16 | VIT-1030-16 | 7/8" | 7/16" | 3-1/2″ | 21 | |

| 10" | 3'' | 5000 | 1-1/4″ | VIR-1030-20 | VIT-1030-20 | 7/8" | 7/16" | 3-1/2″ | 21 | |

| 10" | 3'' | 6000 | 3/4″ | VFR-1030-12 | VFT-1030-12 | 1-3/8" | 11/16" | 3-1/2″ | 31 | |

| 10" | 3'' | 6000 | 1″ | VFR-1030-16 | VFT-1030-16 | 1-3/8" | 11/16" | 3-1/2″ | 31 | |

| 10" | 3'' | 6000 | 1″ | VFR-1030-16-SI | 1-3/8" | 11/16" | 3-1/2″ | 31 | ||

| 10" | 3'' | 6000 | 1-1/4″ | VFR-1030-20 | VFR-1030-20 | 1-3/8" | 11/16" | 3-1/2″ | 31 | |

| 10" | 4" | 10000 | 1-1/4″ | VFR-1040-20-SI | 1-3/4" | 7/8" | 4-1/2″ | 38 | ||

| 10" | 4" | 10000 | 1-1/2″ | VFR-1040-24-SI | 1-3/4" | 7/8" | 4-1/2″ | 38 | ||

| 10" | 4" | 10000 | 2″ | VFR-1040-32 | 1-3/4" | 7/8" | 4-1/2″ | 38 | ||

| 10" | 4" | 15000 | 1-1/4″ | VFT-1040-20 | 1-3/4" | 7/8" | 4-1/2″ | 38 | ||

| 10" | 4" | 15000 | 1-1/2″ | VFT-1040-24 | 1-3/4" | 7/8" | 4-1/2″ | 38 | ||

| 12" | 3'' | 6000 | 3/4″ | VIR-1230-12 | VIT-1230-12 | 7/8" | 7/16" | 3-1/2″ | 39 | |

| 12" | 3'' | 6000 | 1″ | VIR-1230-16 | VIT-1230-16 | 7/8" | 7/16" | 3-1/2″ | 39 | |

| 12" | 3'' | 6000 | 1″ | VIR-1230-16-SI | 7/8" | 7/16" | 3-1/2″ | 39 |

What Are V-Groove Wheels?

V-groove wheels are designed to control the flow of raw materials and finished products. They are common when moving baked goods into an oven, components between machines, transporting loads over long distances, and within a wide array of production line sequences within industrial facilities, warehouses, and manufacturing facilities. Designed with a V-shaped groove along the outside diameter, the wheels provide maximum contact with the track or rail while ensuring even weight distribution. This design helps prevent derailing and swaying. This makes them ideal for scenarios where heavy-loads are encounter and where stability is paramount to protecting product, personnel, and the integrity of the track.

Applications of V-Groove Wheels

We can customize V-groove wheels suitable for your needs and the operational requirements within your facility. At RWM, our V-groove wheels are ideal for use in:

- Conveyor systems

- Industrial carts

- Industrial ovens

- Paint booths

- Large doors

- Hoist trolleys

- And more!

How To Select the Right V-Groove Wheel

We offer a broad range of options that will help you enjoy the superior performance and reliability you need. We will help you select the optimal configuration for your requirements, including the following details:

-

Diameter: We offer wheel diameters of 4 inches to 12 inches.

-

Width: We can manufacturer V-Groove wheels with wheel widths of between 1.5 inches to 4 inches.

-

Axle: Our wheels offer axle diameters of between 0.5 inches to 1.5 inches.

-

Material: We can deliver either cast-iron or forged steel V-groove wheels.

-

Capacity: Our wheels can support loads of between 700 pounds to more than 15,000 pounds.

-

Custom features: We can incorporate wheel seals or Zerk fittings on our wheels.

Benefits of Choosing RWM Casters’ V-Groove Wheels

When you need wheels with enhanced strength, cast iron (VI) or forged steel (VF) are the best materials for use with inverted angle iron track. Our premium VF and VI wheels incorporate straight or tailored roller bearings that we can cut or lengthen with spacers. This allows us to optimize the wheel for use within inverted track, smooth floor surfaces, and more. It also ensures safe and efficient handling of equipment and materials.

Indeed, our high-strength wheels offer many benefits when used in assembly production lines, manufacturing facilities, and other industrial applications. These benefits include:

Strength: Cast-iron or forged steel allows RWM’s V-groove wheels to maintain superior strength in nearly any operational environment.

Versatility: Capable of operating on either an inverted track or flat surface, our VF and VI wheels are a versatile, efficient solution suitable for nearly any industry.

Efficiency: On or off track, our V-groove wheels allow optimal functionality in transporting heavy-duty loads.

Why Choose Us?

At RWM, our teams work hard to set industry standards that others strive to meet. Our American-made wheels are manufactured to the highest quality standards and we guarantee your satisfaction with our customer service and the attention to detail we put into every product. You can depend on us when you want competitive prices, industry-best lead times, and innovations that are second to none.

Need new wheels to help your business improve efficiency, safety, and productivity? Contact the experts at RWM to place a custom order for wheels designed to meet your specific needs.