Rotating turntables and carousels provide 360-degree access to your workstation, even while you stand still. At the heart of the turntable is a swivel section that provides smooth rotational movement.

At RWM Casters, we incorporate our patented Kingpinless™ swivel design in our robust “Lazy Susan” swivel sections for maximum productivity and longevity. This design includes a single-ball bearing that makes full contact with the precision-machined raceway, which is hardened to a minimum of 53 Rockwell C. This ensures smooth turning and dependable operation, even after years of heavy use. All swivel sections also have a lubrication fitting to allow for easy field maintenance.

If your business or institution is looking for turntable swivel sections for industrial use, reach out to RWM Casters at 877-683-0038 or contact us online!

Uses for Industrial Turntable Swivel Sections

Our industrial turntables come in several materials and sizes to achieve capacities ranging from 900 pounds to 30,000 pounds. This gives you numerous options for finding a turntable that meets your needs. Our heavy-duty turntables can take continuous punishment in even the toughest industrial applications, including:

- Industrial workstations

- Weld tables

- Material container stands

- Product displays

- Paint booths

- Dollies in the theatrical industry

Customization Options for Industrial Turntable Swivel Sections

Just as applications for turntable swivel sections differ, so do your customization options. Consider some of the ways you can adapt a turntable to meet your needs:

- Mounting options: Choose an available mounting plate or specify optimized mounting options, including stems, center holes, and tapped holes.

- Swivel locks: Turntables with swivel locks help you work productively without your workstation rotating in either direction. Options include regular, demountable, and L-type swivel locks. Be aware that when adding a swivel lock to most turntables, the grease fitting is removed so the assembly can turn freely. Additionally, bolt clearance is limited with a swivel lock, so welding, flathead, or cap-type screws should be used for mounting.

- Maintenance-free turntables: Some models come with sealed, greased-for-life precision bearings that provide safe, smooth, maintenance-free operation.

- Stainless steel finish: The 65 and 75 Series turntables are available with a stainless steel finish, which makes them corrosion-resistant in environments that could expose the turntable to water, chemicals, and other hazards.

- Zinc plating: This finish comes standard on 47, 48, and 65 Series for rust resistance.

- High-temperature paint: If you plan to use your turntable swivel section in a high-temperature setting, consider this customization option to protect the finish.

Why Choose RWM Casters for Turntable Swivel Sections?

The Kingpinless swivel design of RWM turntables makes them some of the best in the industry. We proudly manufacture our turntable swivel sections in the U.S. for maximum quality assurance. If you’re not certain what size, capacity, finish, mounting option, or other customizations you need, we can help. Our goal is to provide you with high-quality products that meet your needs without fail for matchless customer service and satisfaction. Looking for larger, higher-capacity raceways than those listed here? We can customize your turntable swivel sections to meet the specifications of any project.

For more information on industrial turntable swivel sections or to place your order, please contact RWM Casters at 800-634-7704.

Industrial Turntable FAQs

What are the benefits of maintenance-free turntables?

As the name suggests, these turntables require no maintenance. This makes them a highly convenient option for many applications. If your applications require that your turntables aren’t easily accessible for maintenance, consider a maintenance-free option.

Can turntables be used in high-heat applications?

At RWM, we can manufacture turntables for all types of uses and applications, even ones where temperatures start to soar. If you need a turntable for a high-temperature application, we also offer high-temperature paint so that the finish will stay protected.

If I need a customized turntable, can RWM provide that?

We understand that there’s a wide range of uses that require turntables, so no product can be one-size-fits-all. If you need a custom product, our team will work closely with you to deliver the ideal turntable for your specific needs and applications.

FEATURES

| Raceway Design | Patented Kingpinless™ single ball bearing precision machined raceway hardened to 53 Rockwell C minimum. All swivel sections are supplied with a lubrication fitting for field maintenance. See individual series section for more information. |

| Mounting | Choose an available mounting plate or specify a desired method. Some options include: stems, center holes, and tapped holes. |

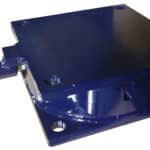

| Finish | Laguna Blue paint. 47, 48 and 65 Series come standard zinc plated. |

*When adding a swivel lock to most turntables the grease fitting is removed to allow free turning of the assembly. Additionally with a swivel lock bolt clearance is limited so welding, flat head or cap type screws will need to be utilized for mounting.

T125-LMRT

| SWIVEL LOCKS | |

| DSL | Demountable Swivel Lock* |

| SL | Swivel Lock |

| LSL | L-Type Swivel Lock |

| LUBRICATIONS | |

| HT | High Temperature Lubrication |

| LT | Low Temperature Lubrication |

| YOKES, RACEWAYS AND MOUNTING | |

| NY | Notched Yoke |

| OM | Optional Mounting |

| SR | Sealed Raceway |

| FINISHES | |

| HTP | High Temperature Paint |

| SS | Stainless Steel (65, 75 only) |

| ZP | Zinc Plated |

| Swivel Section | Mounting Plates | Overall Stack Height | Capacity lbs. | Max. Offset | Approx. Weight | Top Plate size | Bolt Hole Spacing | Optional Center Hole |

|---|---|---|---|---|---|---|---|---|

| 47 | T47-46RT(47STD) | 1-3/16” | 900 | 1-3/16” | 2.6 | 4” x 4-1/2” | 2-5/8” x 3-5/8” slotted to 3” x 3” | 1” |

| 47 | T47-41RT | 1-3/16” | 900 | 1-3/16” | 3.8 | 4” x 5” | 2-5/8” x 3-5/8” slotted to 3” x 4” | 1” |

| 47 | T47-42RT | 1-3/16” | 900 | 1-3/16” | 4.8 | 4-1/2” x 6-1/2” | 2-7/16” x 4-15/16” slotted to 3-3/8” x 5-1/4” | 1” |

| 47 | T47-43RT | 1-3/16” | 900 | 1-3/16” | 4.9 | 5” x 5-1/2” | 4-1/8” x 4-1/2” | 1” |

| 65 | T65-41RT | 1-9/16” | 1500 | 1-3/16” | 4.3 | 4” x 5” | 2-5/8” x 3-5/8” slotted to 3” x 4” | 1” |

| 65 | T65-42RT | 1-9/16” | 1500 | 1-3/16” | 5.3 | 4-1/2” x 6-1/2” | 2-7/16” x 4-15/16” slotted to 3-3/8” x 5-1/4” | 1” |

| 65 | T65-43RT | 1-9/16” | 1500 | 1-3/16” | 5.4 | 5” x 5-1/2” | 4-1/8” x 4-1/2” | 1” |

| 65 | T65-46RT (65STD) | 1-9/16” | 1500 | 1-3/16” | 3.13 | 4” x 4 1/2” | 2 5/8” x 3 5/8” slotted to 3” x 3” | 1” |

| 65 | T65-54RT | 1-13/16” | 1500 | 1-3/16” | 8.13 | 5-1/4” x 7-1/4” | 3-3/8” x 5-1/4” slotted to 4-1/8” x 6-1/8” | 1” |

| 65 | T65-75RT | 1-11/16” | 1500 | 1-3/16” | 6.5 | 4-1/2” x 6-1/2” | 2-7/16” x 4-15/16” slotted to 3-3/8” x 5-1/4” | 1” |

| 75 | T75-75RT | 1-11/16” | 4500 | 1-1/2” | 7.1 | 4-1/2” x 6-1/2” | 2-7/16” x 4-15/16” slotted to 3-3/8” x 5-1/4” | 1-1/2” |

| 75 | T75-76RT | 1-13/16” | 5200 | 1-1/2” | 10.7 | 5-1/4” x 7-1/4” | 3 3/8” x 5 1/4” slotted to 4 1/8” x 6 1/8” | 1-1/2” |

| 75 | T75-90RT | 2-1/16” | 5200 | 1-1/2” | 14.1 | 6” x 7” | 4-5/8” x 5-1/2” slotted to 4-3/8” x 5-5/8” | 1-1/2” |

| 75 | T75-95RT | 2-1/16” | 5200 | 1-1/2” | 15.4 | 6” x 7-1/2” | 4-1/2” x 6” slotted 4-1/8” x 6-1/8” | 1-1/2” |

| 85 | T85-90RT (85STD) | 2-3/8” | 7500 | 2-1/8” | 17.5 | 6” x 7” | 4-5/8” x 5-1/2” slotted to 4-3/8” x 5-5/8” | 2” |

| 85 | T85-95RT | 2-3/8” | 7500 | 2-1/8” | 18.7 | 6” x 7-1/2” | 4-1/2” x 6” slotted 4-1/8” x 6-1/8” | 2” |

| 85 | T85-LLRT | 2-3/8” | 7500 | 2-1/8” | 41.1 | 8-1/2” x 11” | 7” x 9-3/4” | 2” |

| 85 | T85-LMRT | 2-3/8” | 7500 | 2-1/8” | 25.1 | 8-1/2” x 8-1/2” | 7” x 7” | 2” |

| *95 | T95-95RT | 2-1/2” | 10,000 | 2-1/4” | 22.1 | 6-1/4” x 7-1/2” | 4-1/2” x 6” slotted 4-1/8” x 6-1/8” | 1” |

| *95 | T95-LMRT | 2-1/2” | 10,000 | 2-1/4” | 26.7 | 8-1/2” x 8-1/2” | 7” x 7” | 1” |

| 125 | T125-LLRT | 2-7/8” | 30,000 | 3-1/2” | 52.1 | 8-1/2” x 11” | 7” x 9-3/4” | 4” |

| 125 | T125-LMRT (125STD) | 2-7/8” | 30,000 | 3-1/2” | 36.1 | 8-1/2” x 8-1/2” | 7” x 7” | 4” |

* When adding a Swivel Lock option, the Overall Stack Height will be 3″.

Maintenance Free Precision Turntable

| Swivel Section | Mounting Plates | Overall Stack Height | Capacity lbs. | Max. Offset | Approx. Weight |

|---|---|---|---|---|---|

| 48 | T48-46RT(STD) | 1-9/16” | 1200 | 1-3/16″ | 3.4 |

| 48 | T48-42RT | 1-9/16” | 1200 | 1-3/16″ | 5.1 |

| 68 | T68-68RT | 2-1/4” | 2000 | 1-1/2″ | 7.5 |

Stainless Steel Turntable

| Swivel Section | Mounting Plates | Capacity lbs. | Top Plate size | Bolt Hole Spacing |

|---|---|---|---|---|

| S65 | TS65-46RT(S65STD) | 900 | 4″ x 4-1/2″ x 1/4″ | 2-5/8″x3-5/8″ slotted to 3″x3″ |

| S65 | TS65-41RT | 900 | 4” x 5” | 2-5/8” x 3-5/8” slotted to 3” x 4” |

| S65 | TS65-42RT | 900 | 4-1/2” x 6-1/2” | 2-7/16” x 4-15/16” slotted to 3-3/8” x 5-1/4” |

| S65 | TS65-43RT | 900 | 5” x 5-1/2” | 4-1/8” x 4-1/2” |

| S75 | TS75-75RT(S75STD) | 1800 | 4-1/2″ x 6-1/2″ x 1/4″ | 2-7/16″ x 4-15/16″ slotted to 3-3/8″ x 5-1/4″ |

| S75 | TS75-76RT | 1800 | 5-1/4” x 7-1/4” | 3 3/8” x 5 1/4” slotted to 4 1/8” x 6 1/8” |

All dimensions are in inches except for capacity, which is in pounds. Consult the factory for special mounting options and applications. Larger, higher capacity raceways are available. Contact factory for more information.